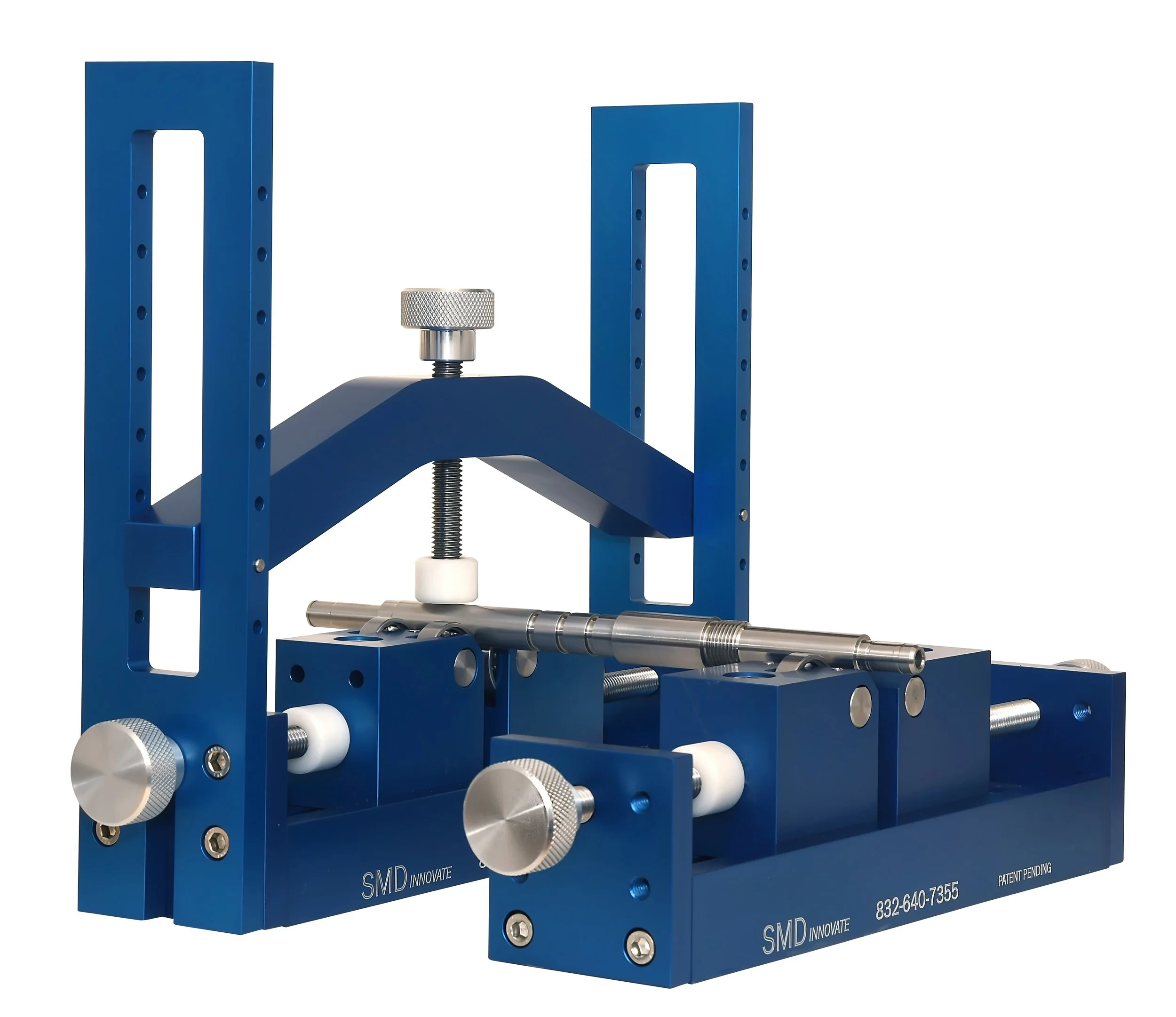

Adjustable Roller V-Block Set

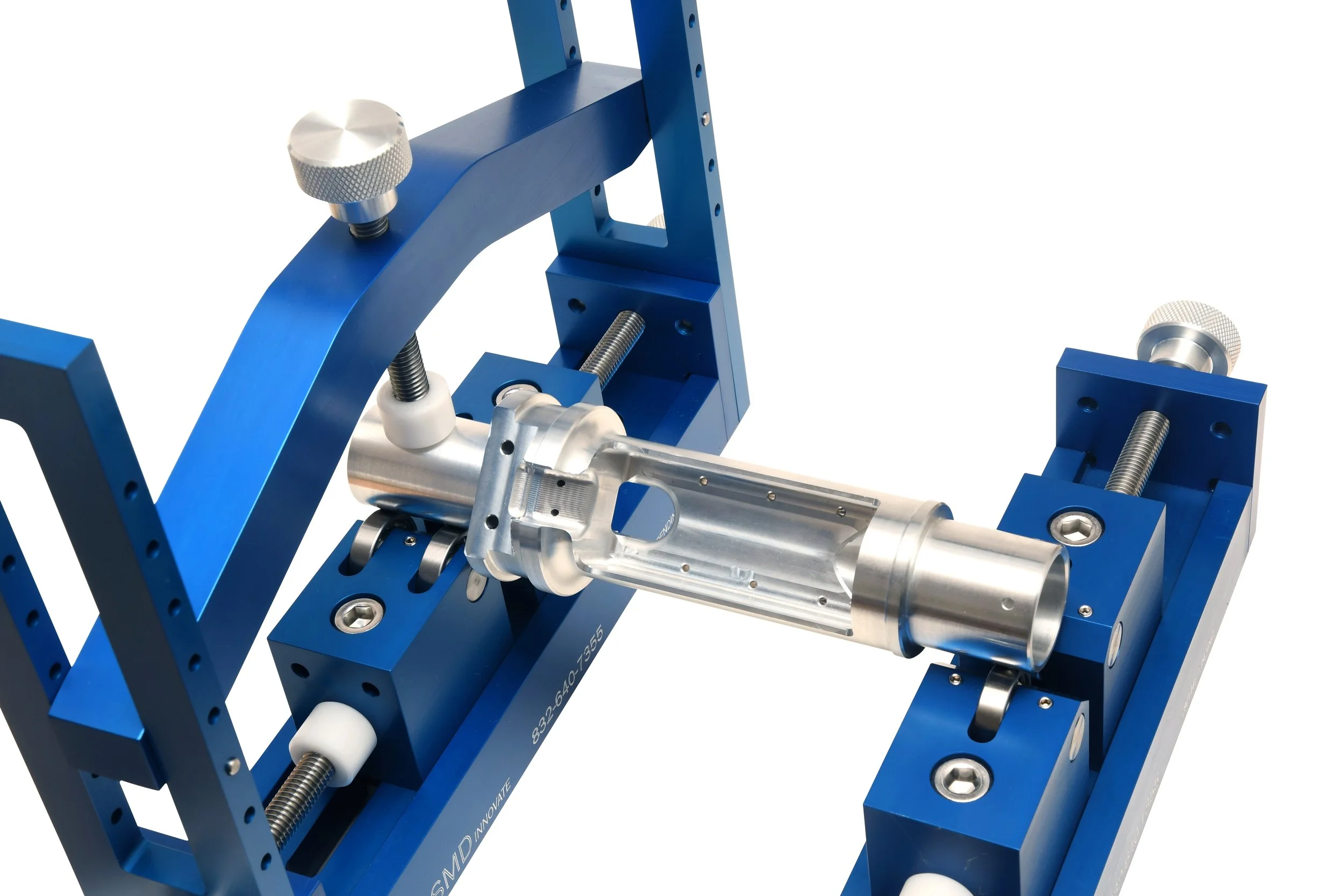

Inspect cylindrical lathe work for concentricity, straightness and T.I.R. (total indicator runout). Great for orienting and locking diametrical and end horizontal work with our A.V.B. Orient and lock into position mill details and short parts with our Industry first "double locking bearing system" and Delrin tipped top clamp. Perfect for inspection rooms with CMM's and other programmable inspection devices. No more scratching precision finishes at the final stage. Features smooth rolling stainless steel ball bearings that adjust out to diameters larger than 16" and as small as .125".

Length only limited to surface plate length

All material non-corrosive

Check concentricity, ID to OD Straightness

PRODUCT DETAILS

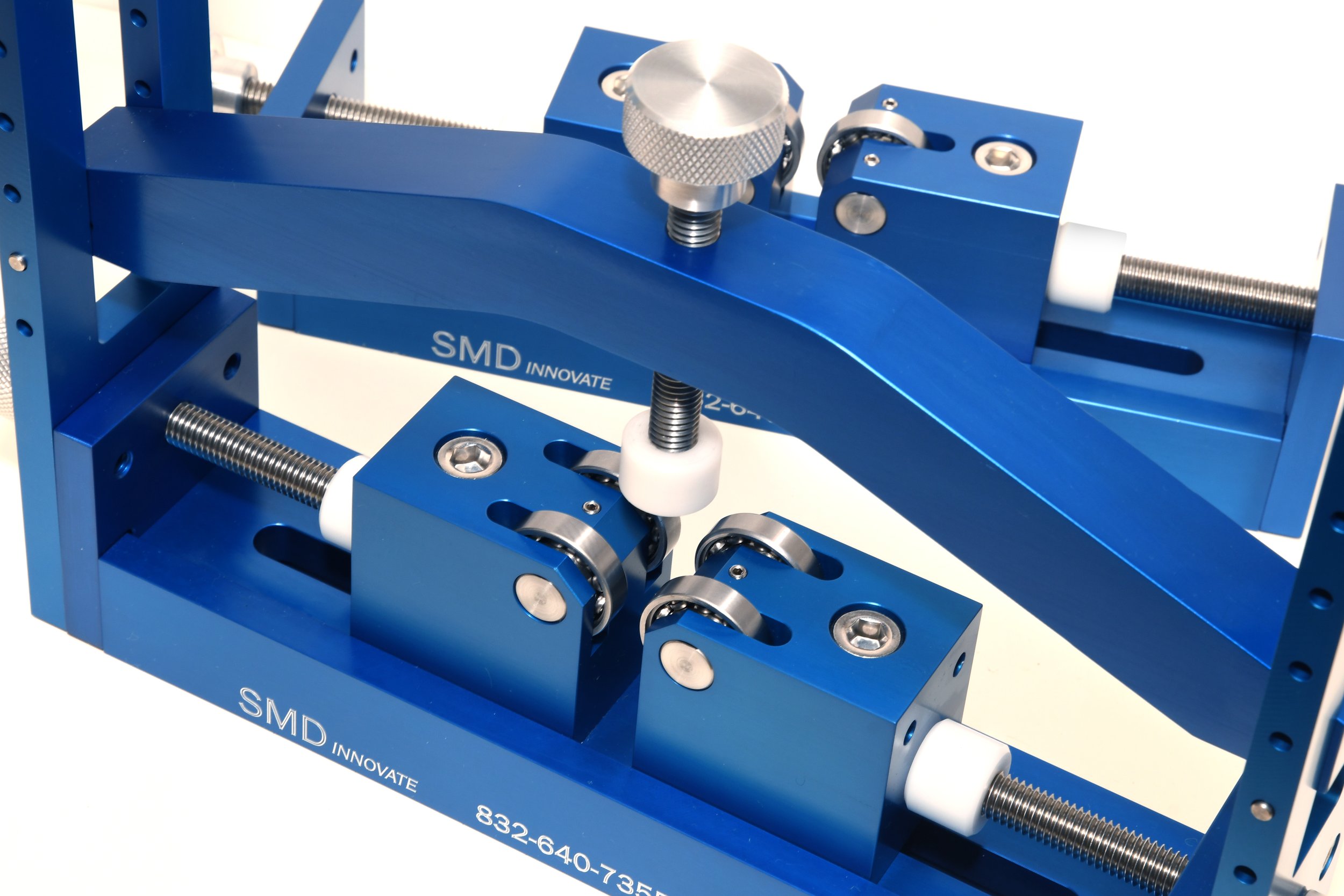

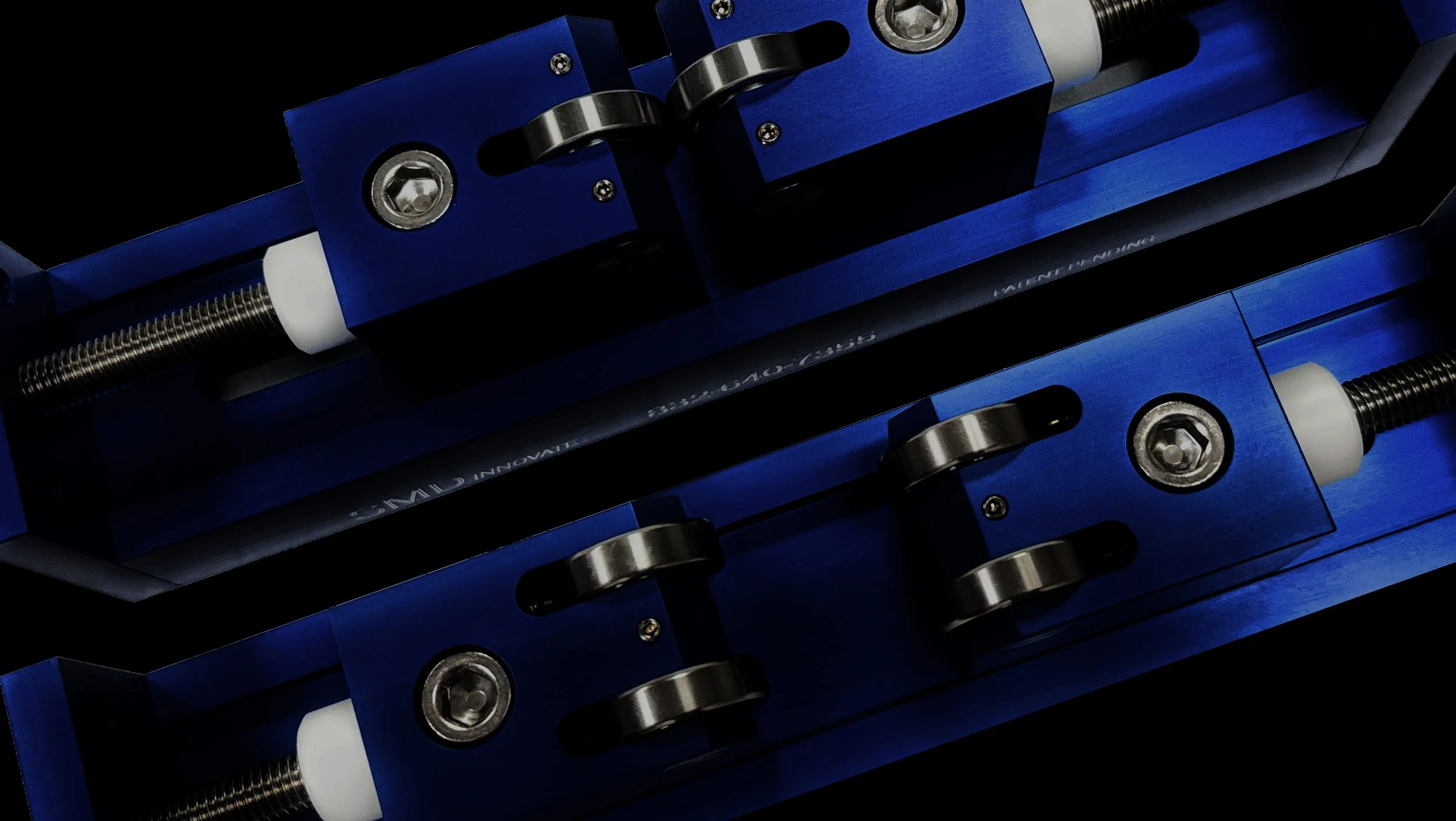

Orient mill details even on short parts with our double bearing slide. Lock part into position with locking bearings and Delrin tipped locking screw on Top Clamp. To level a part simply adjust slides into approximate position. Adjust slides with knurled / delrin adjustment knobs until indicated level and lock slider blocks.

Length only limited to surface plate length

All material non-corrosive

Check concentricity, ID to OD Straightness

.125" to 16.000" diameter capable

Adjustable, capable of dissimilar diameters

Non-scratching ball bearing roller

Top clamp option sold separately

Top clamp allows locking orientation for inspection of end work